Autodesk software

We are now one step closer to 3D printing electronic devices in their entirety. Autodesk is developing Project Wire, a Spark Powered design tool for creating 3D printable electronic devices. We have partnered with Voxel8 to enable the fabrication of truly freeform three-dimensional circuits for the first time.

We are now one step closer to 3D printing electronic devices in their entirety. Autodesk is developing Project Wire, a Spark Powered design tool for creating 3D printable electronic devices. We have partnered with Voxel8 to enable the fabrication of truly freeform three-dimensional circuits for the first time.

We believe future electronic devices will be printed rather than assembled. Fabricated layer-by-layer as a single object, rather than assembled from separate parts. Although 3D printing is often associated with throw-away plastic ‘trinkets’, together with Voxel8 we are looking to make functional printed devices a reality. Today we are starting with electronics by enabling the design of 3D wires embedded in printed models.

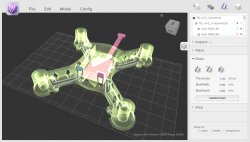

Project Wire is a new design tool under active development at Autodesk that provides electronics and 3D printing enthusiasts with the ability to place components, route 3D wires, and output multi-material print data for fabrication. Key features of Project Wire include:

Components

Components

- 3D component library

- Automatic component orientation

- Component boolean operations

Wiring

- Surface drawing

- In-plane drawing

- Automatic 'staircase' generation

Printing

- Multi-material slice preview

- Component placement pausing

- Seamless printer communication

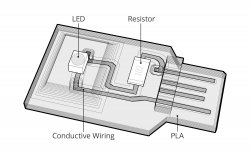

Unlike todays devices that house printed circuit boards within a separate shell, 3D printing enables electronics to be embedded entirely within the structure of the device. Below you can see an example of a simple LED circuit powered via USB.

When this design is printed, the ability to embed conductive 3D wires and components is clear. Project Wire makes the layout, design, and print preparation of these structures very simple.

When this design is printed, the ability to embed conductive 3D wires and components is clear. Project Wire makes the layout, design, and print preparation of these structures very simple.

Circuit prototyping can be done incredibly quickly using Project Wire with the Voxel8 printer. Even more exciting is the ability to design and fabricate circuits that were not previously possible. Wires can be routed in three dimensions to make compact circuits in arbitrary 3D shapes, components can be embedded inside prints to create very robust devices, and each circuit can be customized entirely.

One of the key innovations from Voxel8 is an extremely conductive silver material and deposition system. Voxel8 is co-founded by renowned Harvard University Professor Jennifer A. Lewis, who has spent over a decade developing materials and methods for functional 3D printing. Voxel8's conductive silver material is over 1000 times more conductive than anything available today. The Voxel8 quadcopter reliably powers four motors from 3D printed wires embedded in the quadcopter arms.

Expect Project Wire to be available with the release of the Voxel8 printer later in 2015. The fundamentals of how we fabricate electronic devices are changing. New software tools are needed to design for new hardware capabilities. Through our partnership with Voxel8, we are excited to see how the electronic designs of tomorrow can be created today.

Share on Facebook Share on Twitter

You might also like

|

Autodesk SketchBook Pro 7 Software (Autodesk PSG)

|

|

SketchBook Pro 6 [Old Version] Software (Autodesk PSG)

|